Concreting JSA

JSA, JHA, THA, JSEA or a JHA?

What’s the difference?

A Job Safety Analysis (JSA) also known as a Job Hazard Analysis (JHA), or Task Hazard Analysis (THA), Job Safety and Environemtal Analysis (JSEA) or a Safe Work Method Statement (JHA) in essence are all the same thing.

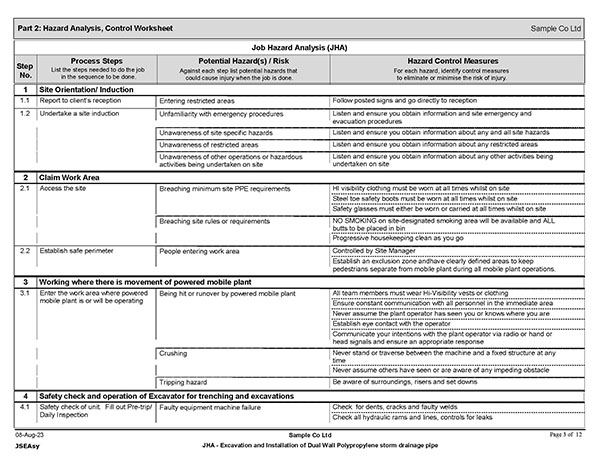

They all have 3 main elements:

- Job Step (What are you going to do)

- Potential Hazard (What can go wrong or cause harm)

- Control measure (What are you going to do to make sure it doesn’t go wrong or cause harm)

A JSEA also considers the environmental hazards/ impacts and controls.

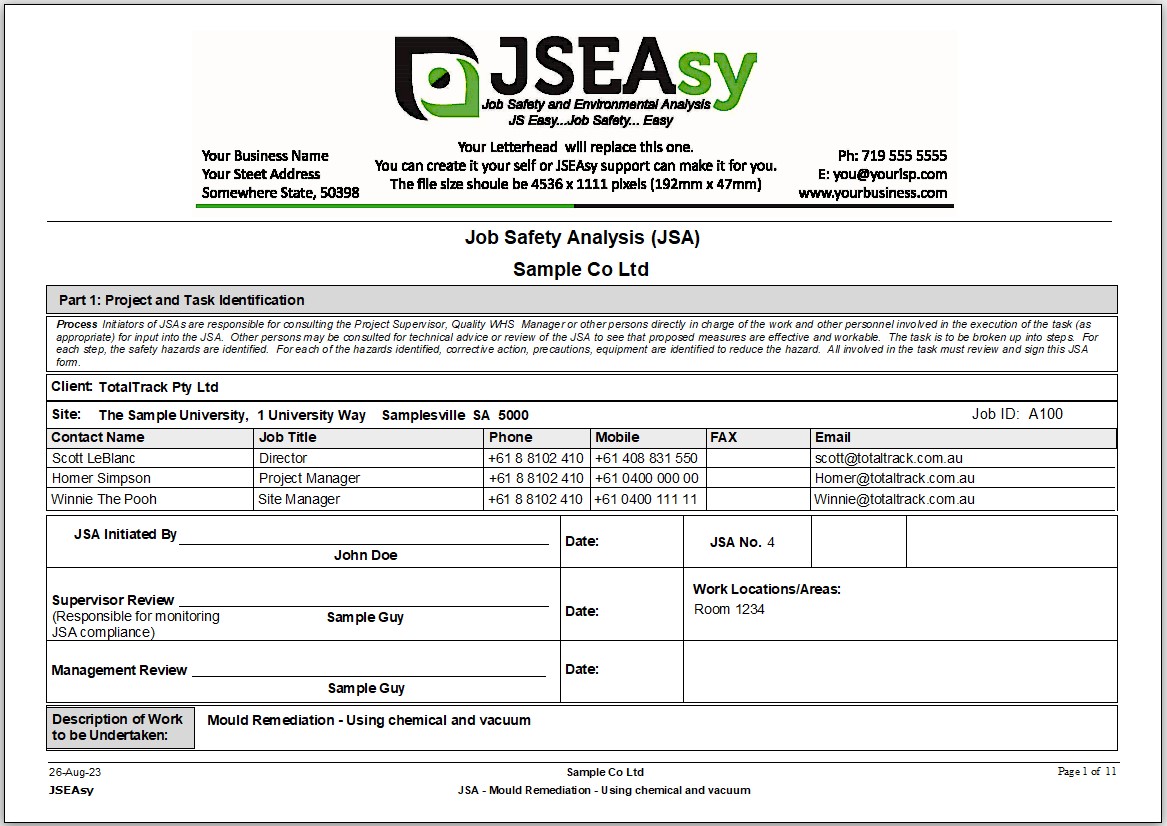

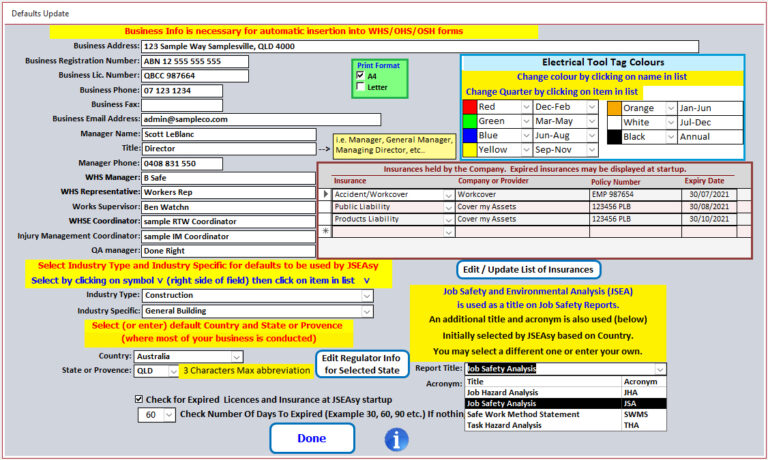

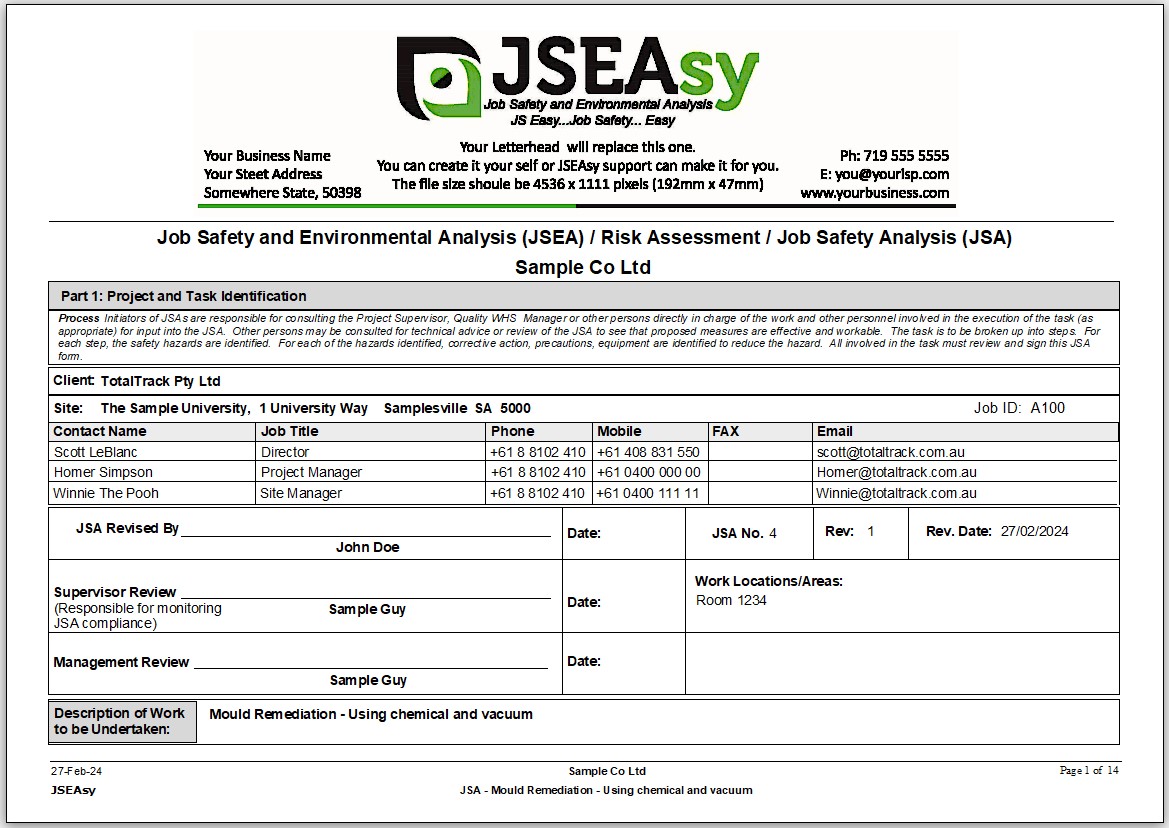

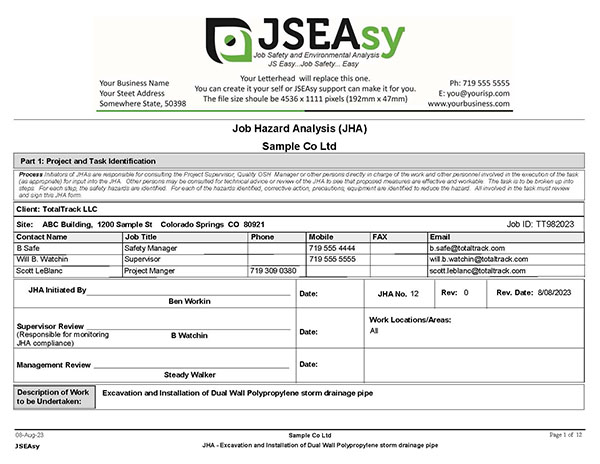

No matter what you call it, The JSEAsy safety Management Software creates a report with the terminology of your choosing.

Set your defaults in the JSEAsy Environmental, Health and Safety Software

A Simplified report or a Full Hybrid report

People often ask, “Can I have a Job Hazard Analysis (JHA) for Concreting Work? A document that covers everything?”

The answer is not really. Well, you could create a document that covers most areas of Concreting work, but it would be hundreds of pages long and would contain more items that did not apply to your project, than items that did.

The process of mixing, pouring, and finishing concrete, involves various hazards.

- Manual Handling: Lifting and moving heavy bags of cement, concrete mix, or tools can lead to strains and musculoskeletal injuries.

- Vibration: Prolonged use of vibrating equipment, such as concrete vibrators, can cause hand-arm vibration syndrome (HAVS).

- Concrete Dust: Inhaling dust generated during concrete mixing and cutting can lead to respiratory issues and irritation.

- Cement Burns: Direct contact with wet cement or concrete can cause skin irritation and chemical burns.

- Working at Heights: Pouring concrete at elevated levels without proper fall protection can result in falls. If there is a risk of a person falling more than 2 metres, it is considered High-Risk Construction work.

- Uneven Surfaces: Uneven or slippery surfaces can contribute to trip and fall incidents.

- Concrete Mixers and Vibrators: The noise generated by concrete mixers and vibrators can contribute to hearing loss if proper protection is not used.

- Power Tools: The use of electrical tools such as concrete saws and drills can pose electrical risks if not used correctly or if equipment is damaged.

- Heavy Machinery: Operating heavy machinery like concrete pumps or mixers without proper training can lead to accidents.

- Tool and Equipment Malfunctions: Malfunctions or misuse of tools and equipment can result in injuries.

- Working in Formwork: Workers may enter confined spaces, such as formwork, where they may be exposed to low oxygen levels or other hazards.

- Extreme Temperatures: Working in extreme temperatures, whether hot or cold, can contribute to heat or cold stress.

- Hand Tools: Improper use of manual tools like shovels, trowels, or screeds can lead to cuts, abrasions, or other injuries.

- Construction Site Traffic: Working in an area with movement of powered mobile plant within a construction site poses significant risks.

A JHA provides a clear, step-by-step guide on how to perform a task safely.

Making JHA has never been easier, just pick your job steps and the JSEAsy safety management software does all the hard work for you.

JSEA/ JHA Example

Below is an example of templates you may insert into your site-specific JHA for a typical complete concreting project.

- Inspect and drive Tip Truck/ Dump Truck

- Arrive at site with truck and trailer and establish unloading area

- Site Orientation/ Induction

- Claim work area

- Unload skid steer loader from trailer using aluminium ramps

- Place rubble around domestic site using a skid steer loader

- Compact area using a petrol-powered vibrating plate

- Installation of simple formwork

- Install damp proof membrane (Forticon plastic)

- Place steel reinforcing mesh

- Concrete Delivery and Pumping

- Placing Concrete

- Push Wheelbarrow on site

- Finishing concrete with petrol powered trowel (Helicopter)

- Load skid steer loader onto trailer using aluminium ramps

- Cleaning up work area

- Monitoring and Review of JHA

Automating the process

When you insert a template, it automatically brings with it:

- The main process step

- The sub process steps associated in undertaking the task

- The potential hazards associated with undertaking the task (you can also delete or add any of these with a simple click)

- The Risk Rating for undertaking the task (You can also change this if you want to)

- The Hazard Control measure (you can also delete or add any of these with a simple click)

- The revised risk rating after applying the control (You can also change this if you want to)

- Any required PPE (you can also delete or add any of these with a simple click)

- Any applicable licenses or qualifications required (you can also delete or add any of these with a simple click)

- Any preoperational inspections required (you can also delete or add any of these with a simple click)

- Any applicable legislation or codes of practice (you can also delete or add any of these with a simple click)

Creating Site-Specific JHA Reports with JSEAsy Safety Management Software

Creating a site-specific JHA is easy using JSEAsy . Once created, you can print/ save a pdf of either a full or simplified SWMS report.

Download an example of a full JHA report generated from the JSEAsy EHS Software.

Download an example of a simplified JHA report generated from the JSEAsy EHS Software.

The JSEAsy software comes preloaded with hundreds of templates (job steps) to build your site-specific JHA with.

Safe Operating Procedures (SOP) and Plant and Equipment Risk Assessments (PERA) are also included in all versions.

The JSEAsy Premium EHS Software is your total WHS management system.

The JSEAsy safety management software is available for download and install on a PC, or hosted in the cloud

JSEAsy Environmental Health and Safety (EHS) Software

Process: Click the Links below to learn more about JSEAsy Safety Management Software and the process.

View an Infographic about How JSEAsy Software works.

See the different versions of the JSEAsy software.

When you buy or Rent JSEAsy you have access to all of the latest version JHA templates, for all trades and industries.

Download the JSEAsy latest version JHA template register.

This is a register sorted by industry type and industry specific of all of the JHA templates included in the latest version of the JSEAsy Safety Management Software.

Save time and Money!

Hundreds of templates included – 1 low price – Exceptional value!

When you buy or rent the JSEAsy Safety Software, not only to get all of the templates specifically for concrete works but you also get all of the templates for all of the other industries and trades as well. Concreters contractors don’t shovel concrete!

You will also benefit from many of the Truck, Civil, Formwork and Carpentry templates.

A list of all the templates included in all versions of the JSEAsy EHS software is shown below.

- You can search by scrolling through the list of all templates.

- You can apply filters to the list by selecting an Industry Type

- You can further refine the list by selecting and industry type and an industry specific.

- You can do key word searches for templates. If you can’t find what you are looking for try:

- Shortening the search term. For example, searching for “deliv” would show deliver and deliveries, but if you searched for deliveries, it would exclude deliver.

- Look for a synonyms/ alternate word for what you are looking for. E.g. tube or pipe

| IndustryType | IndustrySpecific | WorkDescription |

|---|---|---|

| Administration | Office | Photocopying |

| All Industry Types | All Trades | Acceptance of delivery to site for materials |

| All Industry Types | All Trades | Sweeping Floor or ground |

| All Industry Types | All Trades | Site Orientation/ Induction |

| All Industry Types | All Trades | Write up incident report |

| All Industry Types | All Trades | Safety inspection and use of Forklift |

| All Industry Types | All Trades | Site orientation of domestic residence |

| All Industry Types | All Trades | Vacuum |

| All Industry Types | All Trades | Connect hose to existing water supply tap |

| All Industry Types | All Trades | Monitoring and Review of SWMS |

| All Industry Types | All Trades | Inspect and drive passenger/ light commercial vehicle |

| All Industry Types | All Trades | Accept load to vehicle from forklift (3rd Party operator) and Loading by hand |

| All Industry Types | All Trades | Charging of Li-Ion batteries for use with cordless tools |

| All Industry Types | All Trades | Unloading of shipping container with forklift and by hand |

| All Industry Types | All Trades | Working in hot conditions |

| All Industry Types | All Trades | Monitoring and review of JHA |

| All Industry Types | All Trades | Working in Cold Conditions |

| All Industry Types | All Trades | Working in the rain |

| All Industry Types | All Trades | Listening to music while working |

| All Industry Types | All Trades | Working in High Wind Conditions |

| All Industry Types | All Trades | Driving in and out of carparks and on customer premises |

| All Industry Types | All Trades | Driving in and out of carparks and on customer premises |

| All Industry Types | All Trades | Working in an area with the risk of Coronavirus, Covid-19, Influenza or similar |

| All Industry Types | All Trades | Cutting material with a box cutter/ utility knife/ snap blade knife/ sharp tool |

| All Industry Types | All Trades | Working outdoors in hot conditions |

| All Industry Types | All Trades | Electrical Safety |

| Automotive and Plant | Mechanical | Servicing to vehicle in workshop |

| Automotive and Plant | Mechanical | Inspection and use of Four Post Vehicle Hoist |

| Automotive and Plant | Mechanical | Inspection and use of Two Post Vehicle Hoist |

| Automotive and Plant | Mechanical | on site Servicing to diesel powered vehicle |

| Automotive and Plant | Mechanical | Replace diesel fuel filters |

| Automotive and Plant | Mechanical | Replace petrol fuel filters |

| Automotive and Plant | Mechanical | Safety inspection and use of TTX Hydraulic Torque Wrench and hydraulic pump |

| Automotive and Plant | Mechanical | Safety inspection and use of TTS Hydraulic Torque Wrench and hydraulic pump |

| Automotive and Plant | Mechanical | Safety inspection and use of TTL Hydraulic Torque Wrench and hydraulic pump |

| Automotive and Plant | Mechanical | Replace fuel filters |

| Automotive and Plant | Servicing | Servicing to hybrid industrial automatic ride on sweeper/scrubber (Complete job) |

| Automotive and Plant | Servicing | Replace engine oil and filters |

| Automotive and Plant | Servicing | Check batteries and charging system |

| Automotive and Plant | Servicing | Replace hydraulic oil and filters |

| Automotive and Plant | Servicing | Replace radiator coolant |

| Automotive and Plant | Servicing | Jack up vehicle/machine |

| Automotive and Plant | Servicing | Inspection and use of petrol powered air compressor |

| Automotive and Plant | Servicing | Remove and replace wheels using a pneumatic rattle gun |

| Automotive and Plant | Servicing | Replace brake pads using a pneumatic rattle gun |

| Automotive and Plant | Servicing | Inspect/ Repair skirts and scrubber or sweeping brushes |

| Automotive and Plant | Servicing | Replace hydraulic hose |

| Automotive and Plant | Servicing | Grease moving parts and greaseable joints |

| Automotive and Plant | Servicing | Tune engine |

| Automotive and Plant | Servicing | servicing a ride on electric sweeper (Complete Job) |

| Automotive and Plant | Servicing | servicing a walk gas operated behind sweeper/scrubber (Complete Job) |

| Automotive and Plant | Servicing | Change Spark Plugs |

| Automotive and Plant | Servicing | Replace air filter |

| Automotive and Plant | Servicing | Open engine cover/ bonnet/ service compartment |

| Automotive and Plant | Servicing | Check system for gas leaks |

| Automotive and Plant | Servicing | Servicing to hybrid industrial automatic ride on sweeper/scrubber |

| Automotive and Plant | Servicing | on site Servicing to petrol powered vehicle |

| Automotive and Plant | Servicing | Inspection and use of a gasoline powered air compressor |

| Automotive and Plant | Servicing | On site Servicing to gasoline powered vehicle |

| Cleaning | Domestic Cleaning | Mopping Floor |

| Cleaning | Commercial Cleaning | Cleaning of hard surfaces |

| Cleaning | Commercial Cleaning | Cleaning of Rest Rooms / Toilets |

| Cleaning | Commercial Cleaning | Remove bag from bins and waste paper baskets |

| Cleaning | Commercial Cleaning | Steam cleaning of tiles |

| Cleaning | Commercial Cleaning | Inspection and use of planetary floor polisher |

| Cleaning | Commercial Cleaning | Clean bathroom |

| Cleaning | Commercial Cleaning | Clean Glass shower screen with a cloth |

| Cleaning | Commercial Cleaning | Clean Glass with a cloth |

| Cleaning | Commercial Cleaning | Clean mirror with a cloth |

| Cleaning | Commercial Cleaning | Cleaning of residence |

| Cleaning | Commercial Cleaning | Clean Windows with mop and squeegee |

| Cleaning | Commercial Cleaning | Clean Window Using Pure Water Technology |

| Cleaning | Commercial Cleaning | Clean Windows Using rope Access |

| Cleaning | Commercial Cleaning | Gain access to work are using Rope Access |

| Cleaning | Commercial Cleaning | Inspection and use of walk behind battery powered floor scrubber |

| Cleaning | Commercial Cleaning | Inspection and use of High-Speed Propane (LPG) Powered Floor Buffer (Burnisher) |

| Cleaning | Commercial Cleaning | Inspection and use of Carpet Extractor |

| Cleaning | Commercial Cleaning | Inspection and use of Low-Speed Electric Floor Buffer |

| Cleaning | Commercial Cleaning | Cleaning of office and showroom |

| Cleaning | All Cleaning industries | Carpet Cleaning |

| Cleaning | All Cleaning industries | Inspection and use of electric high pressure water sprayer |

| Cleaning | All Cleaning industries | Inspection and use of petrol powered blower/ vacuum |

| Cleaning | All Cleaning industries | Inspection and use of gasoline powered blower/ vacuum |

| Cleaning | All Cleaning industries | Inspection and use of gasoline powered high pressure water sprayer |

| Construction | Roofing | Re-Roofing |

| Construction | Roofing | Visual Inspection of Structure |

| Construction | Roofing | Installation of Safety Mesh to roof area - From EWP |

| Construction | Roofing | Install Temporary Edge Protection from an EWP |

| Construction | Roofing | Loading Roof Sheets or materials with Crane |

| Construction | Roofing | Installation of insulation to roof |

| Construction | Roofing | Installing Roof Sheets – To Flat Roof Area |

| Construction | Roofing | Installation of Support Mesh to walls - Using Scissor Lift |

| Construction | Roofing | Installation of Flashings using a battery powered drill |

| Construction | Roofing | Installation of insulation to walls |

| Construction | Roofing | Installation of wall sheeting from Ground and Scissor Lift |

| Construction | Roofing | Installing External/ Internal Downpipes |

| Construction | Roofing | Install Box Gutter with saddles straps and gutter board |

| Construction | Roofing | Installing Rain Water Heads |

| Construction | Roofing | Form and Flash Roof Penetrations |

| Construction | Roofing | Cutting Roof Sheets with snips |

| Construction | Roofing | Installation of vent ridge |

| Construction | Roofing | Install Pierced Fixed Roof Sheets using a battery powered drill |

| Construction | Roofing | Removal of Asbestos products |

| Construction | Roofing | Roof Plumbing Servicing and Maintenance |

| Construction | Roofing | Install Safety Anchors to an existing roof (Timber from above and below) |

| Construction | Roofing | Removal of wall sheeting |

| Construction | Roofing | Installation of fascia cladding - From a scissor lift |

| Construction | Roofing | Installation of Soffit Sheeting - From EWP |

| Construction | Roofing | Installation of Roof Sheets – To Sprung Curved Roof |

| Construction | Roofing | New-Roofing (Domestic) |

| Construction | Roofing | Removal of materials from roof area by hand - Using EWP |

| Construction | Roofing | Measure Roofing using temporary Anchor Points |

| Construction | Roofing | Passing up Roof Sheets and Accessories from the ground |

| Construction | Roofing | Installation of Metal Fascias from ladder |

| Construction | Roofing | Installation of metal battens |

| Construction | Roofing | Installation of Rain Water Head |

| Construction | Roofing | Installation of Temporary Height Safety System to new roof |

| Construction | Roofing | Installation of Safety Mesh to roof area - From Scaffold |

| Construction | Roofing | Removal of existing roof flashings |

| Construction | Roofing | Removal of Existing RWH |

| Construction | Roofing | Moving materials over the roof |

| Construction | Roofing | Removal of existing Roof Sheeting and Accessories |

| Construction | Roofing | Removal of existing ceiling flashings |

| Construction | Roofing | Removal of Ceiling Sheets |

| Construction | Roofing | Installation of Temporary Static Line |

| Construction | Roofing | Installation of UPVC Pipe |

| Construction | Roofing | Removal of Existing (Flat Roof)- Roof Sheeting |

| Construction | Roofing | Removal of existing Blanket insulation |

| Construction | Roofing | Installation of Air-Cell Insulation |

| Construction | Roofing | Removal of existing Box Gutter |

| Construction | Roofing | Removal of existing Ceiling Insulation from open roof |

| Construction | Roofing | Installation of Safety Mesh to Roof From Roof and Scissor Lift on one side |

| Construction | Roofing | Installation of wall sheeting from Ground and Boom Lift |

| Construction | Roofing | Installation of fascia cladding - From a scaffold |

| Construction | Roofing | Installation of Soffit Sheeting - From Scaffold |

| Construction | Roofing | Installation of Safety Mesh from Roof |

| Construction | Roofing | Installation of Temporary Height Safety System - to Existing roof from Scaffold |

| Construction | Roofing | Removal of existing roof tiles |

| Construction | Roofing | Installation of wall sheeting from Ground and Scaffold |

| Construction | Roofing | Installation of metal Fascia |

| Construction | Roofing | Installation of top hats to masonry wall |

| Construction | Roofing | Installation of Roof walkway |

| Construction | Roofing | Creating Roof Penetrations |

| Construction | Roofing | Installation of roof vents |

| Construction | Roofing | Installation of Static line system |

| Construction | Roofing | Installation of Anchorpoints to existing roof |

| Construction | Roofing | Installation of concealed clip roof decking |

| Construction | Roofing | Remove and Reinstate Roof Screws |

| Construction | Roofing | Remove and reinstate Skylight sheeting |

| Construction | Roofing | Remove and reinstate dektites |

| Construction | Roofing | Remove all materials, equipment and waste from site |

| Construction | Roofing | Installation of Eaves Gutters |

| Construction | Roofing | Installation of Downpipes |

| Construction | Roofing | Install Stone Sheeting |

| Construction | Roofing | Re-fall box gutter |

| Construction | Roofing | Apply silicone to joint |

| Construction | Roofing | Install top hats to steel structure |

| Construction | Roofing | Load materials into boom lift |

| Construction | Roofing | Cut Insulated Panel with a circular saw |

| Construction | Roofing | Fit angles and trims using a battery powered drill and pop rivets |

| Construction | Roofing | Cut metal roof sheets with electric shears |

| Construction | Roofing | Cut metal roof sheets with battery powered shears |

| Construction | Roofing | Cut metal wall sheets with battery powered shears |

| Construction | Roofing | Install Temporary Edge Protection |

| Construction | Roofing | Install variable pitch roof ventilators to metal roof |

| Construction | Roofing | Installation of Temporary Height Safety System - starting from Scissor |

| Construction | Roofing | Removal of existing Roof Sheeting and Accessories |

| Construction | Roofing | Cleanout gutter by hand |

| Construction | Roofing | Installation of Temporary Anchorpoints to existing roof |

| Construction | Roofing | Removal of existing Roof Sheeting and Aceesories |

| Construction | Civil | Site Set Out |

| Construction | Civil | Back Fill trench by hand with original spoil |

| Construction | Civil | Delivery, Safety Check And Use Of Dingo |

| Construction | Civil | Remove spoil from auger using wheel barrow |

| Construction | Civil | Dig Hole by hand |

| Construction | Civil | Mixing concrete with a portable mixer |

| Construction | Civil | Dig hole with power driven auger |

| Construction | Civil | Cutting Bitumen with a Quick Cut Diamond blade saw |

| Construction | Civil | Dig Trench by hand |

| Construction | Civil | Safety inspection and use of wheeled front end loader |

| Construction | Civil | Safety check and operation of Excavator |

| Construction | Civil | Delivery and unloading of mobile plant |

| Construction | Civil | Unload skid steer loader from trailer using aluminium ramps |

| Construction | Civil | Load skid steer loader onto trailer using aluminium ramps |

| Construction | Civil | Load skid steer loader onto truck using aluminium ramps |

| Construction | Civil | Unload skid steer loader from truck using aluminium ramps |

| Construction | Civil | Safety inspection and use of skid steer loader |

| Construction | Civil | Remove soil from domestic site using a skid steer loader and truck |

| Construction | Civil | Arrive at domestic site with truck and trailer and establish unloading area |

| Construction | Civil | Clean street and footpath |

| Construction | Civil | Move soil by hand using a shovel |

| Construction | Civil | Remove rubbish and debris from domestic site using skid steer loader and truck |

| Construction | Civil | Inspect and drive Tip Truck/ Dump Truck |

| Construction | Civil | Dumping/Unloading load on ground using a tip truck/ dump truck |

| Construction | Civil | Spread rubble around site using a skid steer loader |

| Construction | Civil | Place rubble around domestic site using a skid steer loader |

| Construction | Civil | Installation of lintel using a skid steer loader |

| Construction | Civil | Arrive at domestic site with truck and establish unloading area |

| Construction | Civil | Compact area using a petrol powered vibrating plate |

| Construction | Civil | Operation of drilling rig and soil sampling |

| Construction | Civil | Unload skid steer excavator from trailer using aluminium ramps |

| Construction | Civil | Dig trench using a chain trencher |

| Construction | Civil | Back Fill trench using excavator with original spoil |

| Construction | Civil | Compact area using a petrol powered leg rammer |

| Construction | Civil | Set up and use laser level |

| Construction | Civil | Inspection and use of Motor Grader/ Road Grader |

| Construction | Civil | Compact area with Road roller (roller-compactor) |

| Construction | Civil | Safety check and operation of Excavator for trenching and excavations |

| Construction | Civil | Laying asphalt with paver which is filled from tipper |

| Construction | Civil | Laying blue metal paver which is filled from tipper |

| Construction | Civil | Tack coating (including use of hand lance) prior to laying asphalt |

| Construction | Civil | Raising Sewer/ Stormwater Pits and Valve covers in an existing bitumen roadway |

| Construction | Civil | Inspection and use of diesel powered air compressor |

| Construction | Civil | Using a pneumatic Jack Hammer/ pneumatic Breaker/ Demolition Hammer |

| Construction | Civil | Daily preoperational inspection of a Pneumatic Jack Hammer |

| Construction | Civil | Remove and fit attachments on skid steer loader |

| Construction | Civil | Remove and fit attachments on Excavator |

| Construction | Civil | Planning for wet weather and flooding events |

| Construction | Civil | Spreading soil with Shovel and Rake |

| Construction | Civil | Compact area using a gasoline powered leg rammer |

| Construction | Civil | Compact area using a gasoline powered vibrating plate |

| Construction | Civil | Shore trench by Installing Hydraulic Shoring (Soldier set style) |

| Construction | Civil | Inspection and use of Grader/ Scraper |

| Construction | Civil | Back Fill trench using excavator with sand and rubble |

| Construction | Civil | Lift member into place using an excavator |

| Construction | Civil | Site environmental considerations |

| Construction | Civil | Installation of Drag Box/ Trench Box Shoring using an excavator |

| Construction | Carpentry | Manufacture timber wall frames using a mitre saw and Pneumatic (Air) Nail Gun |

| Construction | Carpentry | Stand up wall frames |

| Construction | Carpentry | Installation of Timber Purlins |

| Construction | Carpentry | Cut timber using a circular saw |

| Construction | Carpentry | Installation of Doors and Door Hardware |

| Construction | Carpentry | Cut timber using a reciprocating saw |

| Construction | Carpentry | Cut timber using a battery powered reciprocating saw |

| Construction | Carpentry | Removal of existing doors |

| Construction | Carpentry | Inspection and use of electric air compressor |

| Construction | Carpentry | Cut timber using an electric mitre saw |

| Construction | Carpentry | Nail timber using a pneumatic (Air) nail gun |

| Construction | Carpentry | Nail timber using an Impulse (gas) Nail Gun |

| Construction | Carpentry | Daily preoperational inspection of a Pneumatic (Air) Nail Gun |

| Construction | Carpentry | Daily preoperational inspection of an Impulse (gas) Nail Gun |

| Construction | Carpentry | Cut timber using a jigsaw |

| Construction | Carpentry | Manufacture timber wall frames using a mitre saw and an Impulse (gas) Nail Gun |

| Construction | Carpentry | Installation of eaves linings to new domestic residence |

| Construction | Carpentry | Measure perimeter of house |

| Construction | Carpentry | Create temporary work bench using trestles and planks |

| Construction | Carpentry | Cut fibre cement sheeting using hand operated mechanical shears |

| Construction | Carpentry | Cut fibre cement sheeting using electric shears |

| Construction | Carpentry | Set up trestle scaffold |

| Construction | Carpentry | Cut timber using a battery powered circular saw |

| Construction | Carpentry | Fix fibre cement soffit/ eaves sheet in place and nail by hand |

| Construction | Carpentry | Cut timber beading using a hand saw and mitre box |

| Construction | Carpentry | Measure for cladding above roof |

| Construction | Carpentry | Passing up Sheets and Accessories from the ground |

| Construction | Carpentry | Fix fibre cement cladding sheet in place and nail by hand |

| Construction | Carpentry | Ease/ adjust existing doors |

| Construction | Carpentry | Install timber roof trusses by hand |

| Construction | Carpentry | Install ceiling joist, Hanging beams, stabilisers, etc |

| Construction | Carpentry | Install solid strip timber flooring (Secret Fix) to timber subfloor |

| Construction | Carpentry | Apply construction adhesive using a calking gun |

| Construction | Carpentry | Position floor boards together using a plank jack/ floor dog |

| Construction | Carpentry | Install “STRUCTAflor” particle board flooring |

| Construction | Carpentry | 1st fix carpentry to new dwelling using a Pneumatic and Impulse Nail Gun |

| Construction | Carpentry | Mark out slab using a chalk line |

| Construction | Carpentry | 1st fix carpentry to new 2 story dwelling using a Pneumatic and Impulse Nail Gun |

| Construction | Carpentry | Installation of floor joist |

| Construction | Carpentry | Install plywood flooring |

| Construction | Carpentry | Cut wood beading using a hand saw and mitre box |

| Construction | Carpentry | Cut wood using a battery powered circular saw |

| Construction | Carpentry | Cut wood using a circular saw |

| Construction | Carpentry | Cut wood using an electric jigsaw |

| Construction | Carpentry | Cut wood using an electric mitre saw |

| Construction | Carpentry | Install solid strip wood flooring (Secret Fix) to wood subfloor |

| Construction | Carpentry | Install wood roof trusses by hand |

| Construction | Carpentry | Install wood wall linings using a battery powered drill |

| Construction | Carpentry | Install trimmers/ noggings to wood framing |

| Construction | Carpentry | Install Hebel Panel |

| Construction | Carpentry | Cut Hebel/ Autoclaved Aerated Concrete with a diamond blade circular saw |

| Construction | Plumbing | Back Fill trench by hand with original spoil |

| Construction | Plumbing | Dig Trench by hand |

| Construction | Plumbing | Installation of UPVC pipe |

| Construction | Plumbing | Welding copper tube |

| Construction | Plumbing | Installation of underfloor plumbing and drains |

| Construction | Plumbing | Clean trenches and setting grade by hand |

| Construction | Plumbing | Connect sewer drain to government connection |

| Construction | Plumbing | Working in open trench |

| Construction | Plumbing | Cut into existing earthenware branch using and angle grinder |

| Construction | Plumbing | Connect pipes together using a flexible connector |

| Construction | Plumbing | Load skid steer excavator onto truck/ trailer using aluminium ramps |

| Construction | Plumbing | Installation of Gas storage hot water system (HWS) |

| Construction | Plumbing | Connect water inlet and outlet |

| Construction | Plumbing | Install hot and cold water fist fix plumbing (Timber framed) |

| Construction | Plumbing | Mark out studwork for trimmer and fixture locations |

| Construction | Plumbing | Install trimmers/ nogging to steel framing |

| Construction | Plumbing | Install trimmers/ noggings to timber framing |

| Construction | Plumbing | Install W45 Brass male lugged elbows, breaching pieces and mixers to steel frame |

| Construction | Plumbing | Install damp proof membrane to trimmers/noggings prior to brass fittings |

| Construction | Plumbing | Secure W45 Brass male lugged elbows, breaching pieces and mixers |

| Construction | Plumbing | Install hot and cold water fist fix plumbing (Steel framed) |

| Construction | Plumbing | Run plastic water/ gas pipework and fit off |

| Construction | Plumbing | Fit “T”s and connectors to plastic pipes |

| Construction | Plumbing | Sleeve and apply silicone around pipework passing trough holes |

| Construction | Plumbing | Install temporary caps to fixtures |

| Construction | Plumbing | Pressure testing of hot and cold pipework |

| Construction | Plumbing | Installation of baths |

| Construction | Plumbing | Plumbing final fit |

| Construction | Plumbing | Isolate water to premises |

| Construction | Plumbing | Drain water system |

| Construction | Plumbing | Unpack fixtures/ materials |

| Construction | Plumbing | Fit cover plates and mini cocks to outlets |

| Construction | Plumbing | Cut down UPVC risers using an angle grinder |

| Construction | Plumbing | Install toilet (WC Pan) |

| Construction | Plumbing | Install cistern and flush pipe |

| Construction | Plumbing | Install hand basins |

| Construction | Plumbing | Fit Tapware/ mixers |

| Construction | Plumbing | Install sinks/ troughs |

| Construction | Plumbing | Install dishwasher |

| Construction | Plumbing | Test the property’s gas pipework for pressure leaks |

| Construction | Plumbing | Install gas instantaneous hot water service (HWS) |

| Construction | Plumbing | Install electric storage hot water service (HWS) |

| Construction | Plumbing | Cut down UPVC risers using a battery powered angle grinder |

| Construction | Plumbing | Install Zip Autoboil |

| Construction | Plumbing | Install Stopcock valve |

| Construction | Plumbing | Plug the unit into the power supply outlet |

| Construction | Plumbing | Clearing a blocked drain using an Electric Eel – Drain Snake |

| Construction | Plumbing | Pipe freezing using liquid nitrogen |

| Construction | Plumbing | Service and replacement of TMV in masonry wall |

| Construction | Plumbing | Electro-Fusion Welding of MDPE of HDPE pipe |

| Construction | Plumbing | Install suspended pipework to underside of concrete slab |

| Construction | Plumbing | Fit Pipe insulation over pipes |

| Construction | Plumbing | Glue jointing closed cell elastomeric pipe insulation |

| Construction | Plumbing | Install suspended pipework to underside of roof purlins |

| Construction | Plumbing | Welding/ silver soldering copper pipes together |

| Construction | Plumbing | Drill hole into existing concrete slab with an electric rotary hammer drill |

| Construction | Plumbing | Installation of mechanical masonry anchors |

| Construction | Plumbing | Lift member using a forklift and lifting jib |

| Construction | Plumbing | Run copper plumbing pipework and fit off |

| Construction | Plumbing | Drill hole into existing concrete slab with an electric rotary hammer drill |

| Construction | Plumbing | Install hot and cold water fist fix plumbing (Wood framed) |

| Construction | Plumbing | Install backflow prevention valve |

| Construction | Plumbing | Commercial drainage and hot & cold water reticulation (complete plumbing job 1 ) |

| Construction | Plumbing | Install BlackMAX® SewerMAX® SewerMAX+® pipes |

| Construction | Plumbing | Pumbing and Gas installation to new tennancy |

| Construction | Plumbing | Installation of Dual Wall Polypropylene storm drainage pipe |

| Construction | Plumbing | Drill hole into existing contrete slab with an electric rotary hammer drill |

| Construction | Mechanical Services | Removal and Replacement of gantry crane radio control unit |

| Construction | Mechanical Services | Plumb Lift Shaft |

| Construction | Mechanical Services | Lift shaft rail installation into Masonry shaft |

| Construction | Mechanical Services | Lift Shaft Fitout |

| Construction | Mechanical Services | Lift Car Installation and Fit Out |

| Construction | Mechanical Services | Final connections and commissioning of lift |

| Construction | Mechanical Services | Lift Installation |

| Construction | Mechanical Services | Installation of two post vehicle hoist (complete job including pick up and del) |

| Construction | Mechanical Services | Install hoist motor |

| Construction | Mechanical Services | Connect temporary power supply and test operation of hoist |

| Construction | Mechanical Services | Installation of two post vehicle hoist |

| Construction | Mechanical Services | Installation of four post vehicle hoist (complete job including pick up and del) |

| Construction | Mechanical Services | Installation of four post vehicle hoist |

| Construction | Mechanical Services | Installation of scissor lift vehicle hoist (complete job inc pick up and del) |

| Construction | Mechanical Services | Routine Inspection of 2 post vehicle hoist |

| Construction | Mechanical Services | Routine Inspection of 4 post vehicle hoist |

| Construction | Mechanical Services | Routine Inspection of scissor lift vehicle hoist |

| Construction | Mechanical Services | Install Exhaust hood including ductwork to connect to base building connection |

| Construction | Electrical | Installation of Cable Tray Covers |

| Construction | Electrical | Dig Trench by hand |

| Construction | Electrical | Fit power point to plasterboard wall |

| Construction | Electrical | Fit switch to plasterboard wall |

| Construction | Electrical | Run Cables through existing ceiling space |

| Construction | Electrical | Install Mounting brackets and rails to roof |

| Construction | Electrical | Install isolator |

| Construction | Electrical | Install Inverter |

| Construction | Electrical | Install solar panels onto the mounting frame |

| Construction | Electrical | Connect new cables into existing switchboard |

| Construction | Electrical | Fill out and issue Electrical Certificate of Compliance |

| Construction | Electrical | Test the electrical installation |

| Construction | Electrical | Installation of catenary cable |

| Construction | Electrical | Installation of cable tray |

| Construction | Electrical | Run Cables and secure to catenary cable |

| Construction | Electrical | Connect new cables into electrical plant/ equipment |

| Construction | Electrical | Isolate power to existing system |

| Construction | Electrical | Disconnect electrical from existing plant |

| Construction | Electrical | Rewire in conduits between light fittings |

| Construction | Electrical | Tracing and identifying existing live lighting circuits - for fault purposes |

| Construction | Electrical | Replace existing light fittings |

| Construction | Electrical | Secure conduits to structure with saddles |

| Construction | Electrical | Installation of Solar System to Domestic Dwelling |

| Construction | Electrical | Working in ceiling space |

| Construction | Electrical | Fit power outlet to drywall |

| Construction | Electrical | Fit switch to drywall |

| Construction | Electrical | Electrical installation to new tenancy (Complete Job with scissor lift) |

| Construction | Electrical | Install light fittings |

| Construction | Electrical | Work on or near energised electrical installations or services |

| Construction | Electrical | Replace Smoke Detector |

| Construction | Bricklaying | Bricklaying |

| Construction | Bricklaying | Carry bricks using a mechanical brick carrier (Clamps) |

| Construction | Bricklaying | Cut bricks using a petrol powered brick saw |

| Construction | Bricklaying | Bricklaying to new project home |

| Construction | Bricklaying | Installation of viscourse |

| Construction | Bricklaying | Set up Profolds to corners |

| Construction | Bricklaying | Set up mortar boards |

| Construction | Bricklaying | Mixing cement with a portable petrol powered mixer |

| Construction | Bricklaying | Cut bricks using an angle grinder |

| Construction | Bricklaying | Load bricks onto scaffold by hand |

| Construction | Bricklaying | Installation of lintel by hand |

| Construction | Bricklaying | Wash down brick wall |

| Construction | Bricklaying | Carry blocks by hand |

| Construction | Bricklaying | Acid wash surface by hand |

| Construction | Bricklaying | Mixing cement/ mortar with a portable petrol powered mixer |

| Construction | Bricklaying | Cut bricks using a gasoline powered brick saw |

| Construction | Bricklaying | Mixing cement/ mortar with a portable gasoline powered mixer |

| Construction | Bricklaying | Installation of Glass Blocks to existing opening |

| Construction | Bricklaying | Use of Brick/Materials hoist |

| Construction | Structural Steel | Installing Bolts through existing concrete slab |

| Construction | Structural Steel | Installation of Steel Members - Using a Crane |

| Construction | Structural Steel | Installation of Steel Bracing Members - Using an EWP |

| Construction | Structural Steel | Installation of Roof Purlins - Using a Crane |

| Construction | Structural Steel | Installation of Girts - Using an EWP |

| Construction | Structural Steel | Installation of Steel members by hand |

| Construction | Structural Steel | Lifting members using a chain block |

| Construction | Structural Steel | Installation of Columns by hand |

| Construction | Structural Steel | Concrete filling of Columns by bucket |

| Construction | Structural Steel | Removal of Steel Members by hand using EWP |

| Construction | Structural Steel | Inject Epoxy into holes |

| Construction | Structural Steel | Installation of Dynabolts |

| Construction | Structural Steel | Installation of Steel Members - Using an EWP |

| Construction | Structural Steel | Coring concrete |

| Construction | Structural Steel | Installation of Ball Tube Handrail |

| Construction | Structural Steel | Cleaning steel using an electric grinder with a wire brush attachment |

| Construction | Structural Steel | Grout Columns |

| Construction | Structural Steel | Crane Set Up |

| Construction | Structural Steel | Cutting Steel with an Oxy- Torch |

| Construction | Structural Steel | Lift members into position by hand |

| Construction | Structural Steel | Lifting materials using duct lifters |

| Construction | Structural Steel | Welding cleats to existing structure with a portable electric welder |

| Construction | Structural Steel | Installation of Hold Down bolts into existing Concrete |

| Construction | Structural Steel | Land Column into position with Crane |

| Construction | Structural Steel | Installation of Chem Anchors onto existing masonry wall |

| Construction | Structural Steel | Installation of Wall plate by Hand |

| Construction | Structural Steel | Installation of Floor Grating |

| Construction | Structural Steel | Claim work area on rail line |

| Construction | Structural Steel | Land Member into position using crane |

| Construction | Structural Steel | Drill hole using a magnetic drill |

| Construction | Structural Steel | Tension nuts using a battery powered rattle gun |

| Construction | Structural Steel | Install connecting bolts and tension nuts using a battery powered rattle gun |

| Construction | Structural Steel | Cleaning steel using a battery powered grinder with a wire brush attachment |

| Construction | Structural Steel | Installation of Chem Anchors onto existing masonry surface |

| Construction | Structural Steel | Repairs to a Fuel Vessel |

| Construction | Wall and Ceiling Linings | Manufacture Steel Stud Wall Frames |

| Construction | Wall and Ceiling Linings | Installing Cement Sheet Cladding |

| Construction | Wall and Ceiling Linings | Installation of plasterboard linings |

| Construction | Wall and Ceiling Linings | Flushing to screws and joints in linings |

| Construction | Wall and Ceiling Linings | Sanding of flushed joints by hand |

| Construction | Wall and Ceiling Linings | Cut plasterboard using a key hole plasterboard saw |

| Construction | Wall and Ceiling Linings | Install suspended ceiling grid |

| Construction | Wall and Ceiling Linings | Cut fibre cement sheet using an electric circular fibre cement saw |

| Construction | Wall and Ceiling Linings | Install fibre cement linings |

| Construction | Wall and Ceiling Linings | Installation of insulation Batts to wall and ceiling framing |

| Construction | Wall and Ceiling Linings | Sanding of flushed joints using an electric drywall / plasterboard sander |

| Construction | Wall and Ceiling Linings | Manufacture/ build Steel Stud Wall Frames on site |

| Construction | Wall and Ceiling Linings | Install fibre cement linings using a battery powered drill |

| Construction | Wall and Ceiling Linings | Cut hole into existing Drywall surface using a key hole Drywall saw |

| Construction | Wall and Ceiling Linings | Cut plasterboard using a plasterboard hand saw |

| Construction | Wall and Ceiling Linings | Cut Drywall using a drywall hand saw |

| Construction | Wall and Ceiling Linings | Installation of drywall linings |

| Construction | Wall and Ceiling Linings | Drywall finishing |

| Construction | Wall and Ceiling Linings | Sanding of finished drywall by hand |

| Construction | Wall and Ceiling Linings | Suspended ceiling, steel stud, flush jointed plasterboard (complete job) |

| Construction | Wall and Ceiling Linings | Clean up buckets and tools |

| Construction | Windows and Doors | Install aluminium door frame into existing masonry opening |

| Construction | Windows and Doors | Installation of Aluminium Doors and Door Hardware |

| Construction | Windows and Doors | Cork joint with Polyurethane sealant |

| Construction | Windows and Doors | Installation of Wooden Doors and Door Hardware using battery powered tools |

| Construction | Windows and Doors | Install preassembled window frame into existing opening and screw fix |

| Construction | General Building | Construction Site Establishment and Project Risk Assessment |

| Construction | General Building | Project Risk Assessment |

| Construction | General Building | Install Acro prop |

| Construction | General Building | Remove existing silicone |

| Construction | General Building | Clean up site by hand using a wheel barrow to transfer debris to bin |

| Construction | General Building | Refurbishment of residence/ unit |

| Construction | General Building | Another us |

| Construction | General Building | Install Pull down attic ladder into drywall ceiling and wood framing |

| Construction | General Building | Cut wood using a battery powered reciprocating saw |

| Construction | General Building | Cut wood using a reciprocating saw |

| Construction | General Building | Install Carpet and underlay to a wood floor |

| Construction | General Building | Brick and Blocklaying – Complete commercial job scaffold supplied by builder |

| Construction | General Building | Concrete filling of blockwork by bucket |

| Construction | General Building | Accept load from vehicle with forklift (3rd Party operator) + unloading by hand |

| Construction | General Building | Carrying materials and equipment (Manual Handling) |

| Construction | General Building | Apply Silicone / Liquid Nails / Construction adhesive |

| Construction | General Building | Installation of UPVC Conduit |

| Construction | General Building | Welding with a portable TIG welder |

| Construction | General Building | Lift member into position using a duct/genie lifter |

| Construction | General Building | Apply epoxy floor coating |

| Construction | General Building | Pre work inspection of Plant |

| Construction | General Building | Demolition/ Removal of steel structure using a crane |

| Construction | General Building | Installation of Structural Steel framed structure (Shed) using a crane and EWP |

| Construction | General Building | Working in a commercial kitchen |

| Construction | General Building | Claim Tenancy work area |

| Construction | General Building | Inspection and use of a Non-slewing Telehandler |

| Construction | General Building | Operation of EPS Hot Melting Machine |

| Construction | Demolition | Removal of Asbestos products |

| Construction | Demolition | Cutting Concrete with a Quick Cut Diamond blade saw |

| Construction | Demolition | Demolition of existing plasterboard lined partition stud wall |

| Construction | Demolition | Cut masonry wall with a Quick Cut Diamond blade saw |

| Construction | Demolition | Part demolition of existing brick wall to form new opening |

| Construction | Demolition | Knock out brick s using a hammer |

| Construction | Demolition | Cut steel using a reciprocating saw |

| Construction | Demolition | Demolition of cupboards and built in robes |

| Construction | Demolition | Demolition/ removal of bathroom fixtures and fittings |

| Construction | Demolition | Jimmy/ prise fixtures away from wall |

| Construction | Demolition | Demolition/ Removal of existing wall and floor tiles using an elec jack hammer |

| Construction | Demolition | Using an electric Jack Hammer/ Electric Breaker/ Demolition Hammer |

| Construction | Demolition | Demolition/ Removal of existing carpet and undelay |

| Construction | Demolition | Demolition/ Removal of existing vinyl flooring |

| Construction | Demolition | Removal/ demolition of existing suspended exposed grid ceiling |

| Construction | Demolition | Safety Inspection and use of Hydraulic Shear attachment |

| Construction | Demolition | Remove screws using a battery powered drill |

| Construction | Demolition | Lower materials to ground with ropes |

| Construction | Demolition | Removal of asbestos adhesive from hard surface |

| Construction | Demolition | Demolition/ removal of existing Compactus shelving unit |

| Construction | Demolition | Remove nuts using a battery powered rattle gun |

| Construction | Demolition | Removing friable asbestos-contaminated soil by hand and using an excavator |

| Construction | Demolition | Remediation of asbestos contaminated soil by hand and using general hand tools |

| Construction | Demolition | Remove asbestos clothing |

| Construction | Demolition | Removing non-friable asbestos-contaminated soil by hand and using an excavator |

| Construction | Demolition | Removing friable asbestos by hand |

| Construction | Demolition | Spray PVA Glue with an electric airless sprayer |

| Construction | Demolition | Removing non friable asbestos by hand |

| Construction | Demolition | Remove existing suspended ceiling tiles |

| Construction | Demolition | Safety check and operation of Excavator for demolition works |

| Construction | Demolition | Safety Inspection and use of Hydraulic Rock Breaker |

| Construction | Demolition | Demolition/ removal of existing suspended exposed grid ceiling |

| Construction | Demolition | Demolition of existing Drywall lined partition stud wall |

| Construction | Demolition | Demolition/ Removal of timber planking by hand |

| Construction | Demolition | Demolition/ removal of existing ceiling tiles |

| Construction | Demolition | Lead based paint removal using Peel away Paint Removal System |

| Construction | Demolition | Selection and Use of PPE |

| Construction | Demolition | Enter asbestos removal area through the Decontamination Unit |

| Construction | Demolition | Exit asbestos removal area through the Decontamination Unit |

| Construction | Demolition | Decontamination of Plant |

| Construction | Demolition | Lining of the Truck with Plastic Lining |

| Construction | Demolition | Demolition of existing flush jointed plasterboard ceiling |

| Construction | Demolition | Demolition/ Removal of existing insulated panel cool room/ freezer by hand |

| Construction | Demolition | Demolition/ removal of existing joinery |

| Construction | Demolition | Demolition of brick veneer iron roof house by hand |

| Construction | Demolition | Removal of materials from roof by hand to ground |

| Construction | Demolition | Demolition/ removal of existing timber framing using a petrol powered chainsaw |

| Construction | Demolition | Demolition/removal of items containing lead |

| Construction | Demolition | Demolition/removal of window glazing and aluminium frames |

| Construction | Demolition | Demolition/removal of glass from frame |

| Construction | Demolition | Demolition/ Removal of Glass Panes in French Doors/ Windows |

| Construction | Demolition | Demolition of brick wall by hand and jack hammer |

| Construction | Demolition | Demolition of brick veneer tiled roof house by hand |

| Construction | Demolition | Passing down Roof Sheets and Accessories to the ground |

| Construction | Demolition | Clean up demolished materials using a shovel, rake, and wheelbarrow. |

| Construction | Demolition | Demolition/ Removal of steel staircase by hand from a scissor lift |

| Construction | Demolition | Demolition/ Removal of Glass Panes in Doors/ Windows |

| Construction | Demolition | Demolition/ Removal of existing pavers |

| Construction | Demolition | Demolition/removal of items containing lead and lead dust to ceiling cavities |

| Construction | Demolition | Vacuum ceiling cavities with a portable HEPA vacuum |

| Construction | Demolition | Removal of contaminated materials/ hazardous waste from site |

| Construction | Demolition | Remove PPE/ Lead contaminated clothing |

| Construction | Demolition | Demolition/ Removal of roller door using a scissor lift and forklift |

| Construction | Demolition | Demolition/ Removal of glazed (Glass) aluminium partitions |

| Construction | Demolition | House demolition using an excavator |

| Construction | Demolition | Removal of demolished materials and waste from site |

| Construction | Demolition | Asbestos removal by hand and house demolition using an excavator |

| Construction | Demolition | Using a portable electric conveyor |

| Construction | Demolition | Mould Remediation - Using chemical and vacuum |

| Construction | Demolition | Inspection and use of a diesel walk-behind floor saw |

| Construction | Demolition | Inspection and Use of a Petrol-Powered Ring Saw to cut masonry surface |

| Construction | Demolition | Inspection and Use of a Gasoline-Powered Ring Saw to cut masonry surface |

| Construction | Demolition | Inspection and Use of a Petrol-Powered concrete chainsaw |

| Construction | Demolition | Inspection and Use of an electric masonry wall saw |

| Construction | Demolition | Prepare to demolish/ remove existing mechanical services |

| Construction | Demolition | Demolish/ remove a wooden staircase by hand |

| Construction | Demolition | Demolition/ removal of existing timber framing using a battery recipro saw |

| Construction | Demolition | Removing non friable asbestos by hand (Complete Job) |

| Construction | Demolition | Don personal protective equipment (PPE) prior to asbestos removal |

| Construction | Demolition | Demolish masonry structure with an electric Demolition Robot |

| Construction | Demolition | Plan the demolition works and sequencing |

| Construction | Demolition | Demolition/ Removal of metal wall cladding by hand from ground and scissor lift |

| Construction | Demolition | Demolition/ Removal of steel framing members by hand from EWP |

| Construction | Home Improvements | Drill Wall Girths and Purlins with an electric drill |

| Construction | Home Improvements | Build Steel Wall Frame and Bolt Wall Girths to Columns |

| Construction | Home Improvements | Build Wall Frame and Tek Screw Wall Girths to Columns |

| Construction | Home Improvements | Stand up clad walls |

| Construction | Home Improvements | Installation of Garage (Domestic Shed) complete job |

| Construction | Home Improvements | Installation of Steel Portal Roof Trusses by hand |

| Construction | Home Improvements | Installation of Steel Roof Purlins by hand |

| Construction | Home Improvements | Installation of Steel Wall Girths by hand |

| Construction | Home Improvements | Installation of wall sheeting from Ground |

| Construction | Home Improvements | Screw fixing wall sheeting from platform ladder |

| Construction | Home Improvements | Mixing concrete with a portable mixer |

| Construction | Home Improvements | Push Wheel Barrow on site |

| Construction | Home Improvements | Wash out mixer |

| Construction | Home Improvements | Installation of Temporary Height Safety System - Starting from Platform Ladder |

| Construction | Home Improvements | Installation of Roller Door (domestic) |

| Construction | Home Improvements | Screw fixing wall sheeting from platform ladder |

| Construction | Home Improvements | Srew fixing wall sheeting from platform ladder |

| Construction | Precast | Joint Caulking |

| Construction | Precast | Propping/Bracing of existing walls |

| Construction | Landscaping | Screed sand |

| Construction | Landscaping | Lay brick pavers |

| Construction | Landscaping | Trowel cement to edges of pavers |

| Construction | Landscaping | Prepare and lay brick pavers |

| Construction | Landscaping | Sweeping sand over pavers and into cracks |

| Construction | Landscaping | Installation of Synthetic Turf |

| Construction | Landscaping | Preparation and installation of synthetic turf |

| Construction | Landscaping | Installation of subsurface irrigation system |

| Construction | Landscaping | Install irrigation poly pipe and fittings |

| Construction | Landscaping | Planting of trees and shrubs by hand |

| Construction | Landscaping | Acceptance of delivery of concrete |

| Construction | Concreter and Concrete Repair | Pouring Concrete |

| Construction | Concreter and Concrete Repair | Dig Trench by hand |

| Construction | Concreter and Concrete Repair | Mixing concrete with a portable mixer |

| Construction | Concreter and Concrete Repair | Dig Hole by hand |

| Construction | Concreter and Concrete Repair | Install damp proof membrane (Forticon plastic) |

| Construction | Concreter and Concrete Repair | Place steel reinforcing mesh |

| Construction | Concreter and Concrete Repair | Finishing concrete with petrol powered trowel (Helicopter) |

| Construction | Concreter and Concrete Repair | Concrete Delivery and Pumping |

| Construction | Concreter and Concrete Repair | Placing Concrete |

| Construction | Concreter and Concrete Repair | Pouring Concrete Slab using a pump and a helicopter |

| Construction | Concreter and Concrete Repair | Concrete crack repair and injection |

| Construction | Concreter and Concrete Repair | Apply surface sealant material (Kahfill) to face of crack |

| Construction | Concreter and Concrete Repair | Injection of Nitofill LV epoxy resin |

| Construction | Concreter and Concrete Repair | Water ingress repair using XYPEX |

| Construction | Concreter and Concrete Repair | Concrete and reinforcement repairs |

| Construction | Concreter and Concrete Repair | Abrasive blasting |

| Construction | Concreter and Concrete Repair | Apply high strength repair mortar |

| Construction | Concreter and Concrete Repair | Finishing concrete with gasoline powered trowel (Helicopter) |

| Construction | Concreter and Concrete Repair | Working with silica and silica containing products |

| Construction | Concreter and Concrete Repair | Installation of Gypsum Concrete floor underlayment |

| Construction | Concreter and Concrete Repair | Inspection and use of Diesel-Powered Hydraulic Cementitious Products Mixer Pump |

| Construction | Concreter and Concrete Repair | Spreading Gypsum Concrete with Rake/Screed |

| Construction | Wall and Floor Tiling | Mixing cement with a portable electric mixer |

| Construction | Wall and Floor Tiling | Placing a cement screed |

| Construction | Wall and Floor Tiling | Wall and floor tiling to domestic residence |

| Construction | Wall and Floor Tiling | Laying floor tiles |

| Construction | Wall and Floor Tiling | Cut tiles using an angle grinder |

| Construction | Wall and Floor Tiling | Mix adhesive in a bucket using an electric drill |

| Construction | Wall and Floor Tiling | Laying wall tiles |

| Construction | Wall and Floor Tiling | Mix grout in a bucket using an electric drill |

| Construction | Wall and Floor Tiling | Grout tiles |

| Construction | Wall and Floor Tiling | Wash out bucket |

| Construction | Wall and Floor Tiling | Remove existing grout between tiles |

| Construction | Painting and Decorating | Painting of Walls and Ceilings |

| Construction | Painting and Decorating | Painting of walls |

| Construction | Painting and Decorating | Painting of ceilings |

| Construction | Painting and Decorating | Painting with an electric airless sprayer |

| Construction | Painting and Decorating | Fill holes and imperfections |

| Construction | Solid Plastering | Rendering/ solid plastering |

| Construction | Solid Plastering | Mix acrylic render in a bucket using an electric drill |

| Construction | Solid Plastering | Trowel acrylic render onto surface |

| Construction | Solid Plastering | Chip out loose concrete/ cement or render with scabbling hammer |

| Construction | Solid Plastering | Clean masonry surface using an electric grinder and cup disc |

| Construction | Solid Plastering | Mixing Adhesive/ Mortar/ Render/ Cement based products with an electric drill |

| Construction | Solid Plastering | Inspection and use of electric mortar / grout / plaster mixer |

| Construction | Fire Protection | Thread pipe using a Portable Power Pipe Threader |

| Construction | Fire Protection | Run Pipe work and cables through existing ceiling space |

| Construction | Fire Protection | Fit speakers and detectors to plasterboard ceiling |

| Construction | Fire Protection | Connect new cables into existing fire panel |

| Construction | Fire Protection | Working in a confined space |

| Construction | Fire Protection | Install suspended fire pipework to underside of roof purlins |

| Construction | Fire Protection | Install suspended fire pipework to underside of concrete slab |

| Construction | Fire Protection | Fit speakers and detectors to drywall ceiling |

| Construction | Floor Finisher and Coverer | Inspection and use of Diamond Floor Grinder |

| Construction | Floor Finisher and Coverer | Install vinyl floors |

| Construction | Floor Finisher and Coverer | Install vinyl skirting |

| Construction | Floor Finisher and Coverer | Install Carpet and underlay to a timber floor |

| Construction | Floor Finisher and Coverer | Install Carpet and underlay to a concrete floor |

| Construction | Glazier | Carrying Window frames from storage area to work area |

| Construction | Glazier | Unload glass from vehicle onto trolley |

| Construction | Glazier | Install Aluminium deflection head and sub sill |

| Construction | Glazier | Cut aluminium sections using an electric mitre saw |

| Construction | Glazier | Install window frames into deflection head and sub sill |

| Construction | Glazier | Install glass into frame |

| Construction | Glazier | Installation of Glazed aluminium partitions |

| Construction | Rigging | Installation of Columns - Using a Crane |

| Construction | Rigging | Installation of steel cable |

| Construction | Rigging | Industrial rope access |

| Construction | Rigging | Install, beams, rafters, bracing and other members using a crane |

| Construction | Rigging | Access work area using a personnel crane cage/ dog box/ workbox |

| Construction | Roof Tiling | Re-bed tiled roof ridge capping |

| Construction | Roof Tiling | Mix mortar in a wheel barrow |

| Construction | Roof Tiling | Carrying mortar in a bucket to work area |

| Construction | Roof Tiling | Set up mortar bed formwork frame |

| Construction | Roof Tiling | Place tile onto mortar bed and trowel off |

| Construction | Roof Tiling | Repointing of ridge tiles |

| Construction | Roof Tiling | Replace broken roof tiles |

| Construction | Scaffolder | Erection and use of a steel tube scaffold |

| Construction | Scaffolder | Erection and use of aluminium tube scaffold |

| Construction | Scaffolder | Installation of cantilevered K-Stage Modular Steel Scaffold |

| Construction | Scaffolder | Installation of K-Stage Modular Steel Scaffold |

| Construction | Scaffolder | Erecting, Altering and Dismantling Prefabricated Steel Modular Scaffolding |

| Construction | Scaffolder | Erection and Use of Mobile Scaffold (Extended Version) |

| Construction | Formworker | Installation of simple formwork |

| Construction | Formworker | Installation of formwork support frames |

| Construction | Formworker | Install bearers and joists to formwork support frames |

| Construction | Formworker | Install plywood formwork to support framing |

| Construction | Formworker | Stripping formply |

| Construction | Formworker | Install ‘Bondek’ or Similar formwork to structure Using an Explosive Power Tool |

| Construction | Formworker | Using an Explosive Power Tool |

| Construction | Steel Fixer | Place steel reinforcing in footing |

| Construction | Steel Fixer | Cut steel reinforcing using bolt cutters |

| Construction | Steel House Framing | Installation of steel house framing |

| Construction | Steel House Framing | Install steel roof trusses by hand |

| Construction | Steel House Framing | Install steel ceiling battens, stabilisers, etc |

| Construction | Steel House Framing | Installation of metal roof battens and trimmers |

| Construction | Air Conditioning and Refrigeration | Installation of threaded rod hanging bars |

| Construction | Air Conditioning and Refrigeration | Installation of support angles or channels to hanging rods |

| Construction | Air Conditioning and Refrigeration | Cut copper pipe with tube cutter |

| Construction | Air Conditioning and Refrigeration | Cut Steel/ Unistrut with drop saw |

| Construction | Air Conditioning and Refrigeration | Filling & testing of pipework |

| Construction | Air Conditioning and Refrigeration | Replacement of wall hung split system air conditioner |

| Construction | Air Conditioning and Refrigeration | Reclaim refrigerant gas from existing system |

| Construction | Air Conditioning and Refrigeration | Disconnect pipework form existing plant |

| Construction | Air Conditioning and Refrigeration | Remove existing wall mounted unit |

| Construction | Air Conditioning and Refrigeration | Install new wall mounted unit |

| Construction | Air Conditioning and Refrigeration | Access ceiling space via Ladder |

| Construction | Air Conditioning and Refrigeration | Run Pipe work through existing ceiling space |

| Construction | Air Conditioning and Refrigeration | Install flexi ductwork and zone motors in ceiling space |

| Construction | Air Conditioning and Refrigeration | Install ceiling registers |

| Construction | Air Conditioning and Refrigeration | Refrigerant charge the system using a vacuum pump |

| Construction | Air Conditioning and Refrigeration | Installation of wall hung split system air conditioner |

| Construction | Air Conditioning and Refrigeration | Replacement of ducted system air conditioner |

| Construction | Air Conditioning and Refrigeration | Installation of ducted system air conditioner |

| Construction | Air Conditioning and Refrigeration | Installation of Cool Room |

| Construction | Air Conditioning and Refrigeration | Fix aluminium channels to existing slab using battery powered hammer drill |

| Construction | Air Conditioning and Refrigeration | Stand up cool room panels and fit into bottom track |

| Construction | Air Conditioning and Refrigeration | Install insulated ceiling panels to cool room |

| Construction | Air Conditioning and Refrigeration | Cut aluminium angles using a hacksaw and mitre box |

| Construction | Air Conditioning and Refrigeration | Installation of refrigeration system to cool room |

| Construction | Air Conditioning and Refrigeration | Hang Fan cooler unit inside cool room |

| Construction | Air Conditioning and Refrigeration | Install TX Valve |

| Construction | Air Conditioning and Refrigeration | Silver solder copper pipes together |

| Construction | Air Conditioning and Refrigeration | Run connecting copper pipework and fit off |

| Construction | Air Conditioning and Refrigeration | Fit Pipe insulation over pipes |

| Construction | Air Conditioning and Refrigeration | Secure pipework to structure with saddles |

| Construction | Air Conditioning and Refrigeration | Core hole through masonry wall with a battery powered rotary hammer drill |

| Construction | Air Conditioning and Refrigeration | Hang condensing unit onto masonry wall |

| Construction | Air Conditioning and Refrigeration | Fit Unistrut brackets onto masonry wall |

| Construction | Air Conditioning and Refrigeration | Mount condensing unit onto preinstalled Unistrut brackets |

| Construction | Air Conditioning and Refrigeration | Pressure testing of pipework with nitrogen and charge with refrigerant (HCFC) |

| Construction | Air Conditioning and Refrigeration | Installation of underfloor refrigeration pipework |

| Construction | Air Conditioning and Refrigeration | Place copper pipes into trench ducting |

| Construction | Air Conditioning and Refrigeration | Mixing Polyurethane Isocyanate in a bucket using an electric drill |

| Construction | Air Conditioning and Refrigeration | Pour Polyurethane Isocyanate into pipe duct |

| Construction | Air Conditioning and Refrigeration | Installation of new refrigeration System to new supermarket (complete job) |

| Construction | Air Conditioning and Refrigeration | Cut hole into existing plasterboard ceiling using a key hole plasterboard saw |

| Construction | Air Conditioning and Refrigeration | Installation of new refrigeration to coolroom (complete job) |

| Construction | Waterproofing | Install waterproofing polymer cementitious membrane |

| Construction | Waterproofing | Hot Fluid-Applied Rubberized Asphalt Waterproofing |

| Construction | Waterproofing | Spray primer onto surface using a hand sprayer |

| Construction | Waterproofing | Heat rubberized asphalt in an oil- or air-jacketed melter |

| Construction | All Trades | Acceptance of delivery to site for materials via Crane Truck |

| Construction | All Trades | Using an Angle Grinder |

| Construction | All Trades | Cleaning up work area |

| Construction | All Trades | Welding with a portable Electric Welder |

| Construction | All Trades | Moving materials around on a trolley |

| Construction | All Trades | Apply touch up paint |

| Construction | All Trades | Access roof via Scissor Lift |

| Construction | All Trades | Access roof via Ladder |

| Construction | All Trades | Using an Existing roof anchorpoint system |

| Construction | All Trades | Drill hole using an electric drill |

| Construction | All Trades | Install screws using a tek gun |

| Construction | All Trades | Cut materials using an electric mitre saw |

| Construction | All Trades | Loading materials onto truck using a crane and by hand |

| Construction | All Trades | Safety Check And Use Of Scissor Lift (Extended version) |

| Construction | All Trades | Safety Check And Use Of Boom Lift (extended version) |

| Construction | All Trades | Access work area via a mobile scaffold |

| Construction | All Trades | Cut Steel using an Angle Grinder |

| Construction | All Trades | Claim Work Area |

| Construction | All Trades | Loading Materials onto roof using an EWP |

| Construction | All Trades | Carrying materials from storage area to work area |

| Construction | All Trades | Push Wheel Barrow on site |

| Construction | All Trades | Access roof via fixed access ladder |

| Construction | All Trades | Marking Out Slab or Ground |

| Construction | All Trades | Erection and use of mobile scaffold |

| Construction | All Trades | Access work area using a platform ladder |

| Construction | All Trades | Install screws using a Battery Powered Drill |

| Construction | All Trades | Drill hole using a Battery Powered Drill |

| Construction | All Trades | Refuelling of machinery |

| Construction | All Trades | Inspection and use of Generator |

| Construction | All Trades | Cut strapping off around pack of materials |

| Construction | All Trades | Inspection and use of petrol powered high pressure water sprayer |

| Construction | All Trades | Access Roof via scaffold stair access |

| Construction | All Trades | Undertake Clients general all sites induction |

| Construction | All Trades | Repeat the above process steps until completion of task |

| Construction | All Trades | Inform facilities / operations and security personnel of work location(s) |

| Construction | All Trades | Drill hole into masonry surface with a battery powered rotary hammer drill |

| Construction | All Trades | Move materials using a trolley (sack Truck) |

| Construction | All Trades | Working in isolation |

| Construction | All Trades | Access roof via Boom Lift |

| Construction | All Trades | Working at height from a scissor lift |

| Construction | All Trades | Inspect and drive passenger/ light commercial vehicle on or off site |

| Construction | All Trades | Access work area using a step ladder |

| Construction | All Trades | Access work area via a scaffold/ working at heights from a scaffold |

| Construction | All Trades | Drill hole into masonry surface with an electric rotary hammer drill |

| Construction | All Trades | Working at heights - Generally |

| Construction | All Trades | Working at height from a boom lift |

| Construction | All Trades | Cut steel using a battery powered angle grinder |

| Construction | All Trades | Working at heights - Generally |

| Construction | All Trades | High Risk Construction Work covered in this SWMS |

| Construction | All Trades | Working where there is movement of powered mobile plant |

| Construction | All Trades | Access work area using 'Hop-Up' trestle ladder/ work platform |

| Construction | All Trades | Access roof via an extension ladder |

| Construction | All Trades | Site Emergency Response Procedure |

| Construction | All Trades | Load materials/members into scissor lift |

| Construction | All Trades | Shoot nail into concrete with a cordless nailer |

| Construction | All Trades | Core through masonry surface with an electric core drill |

| Construction | All Trades | Install concrete screw anchor/bolts using a battery powered rattle gun |

| Construction | Fencing | Delivery and installation of temporary fencing |

| Construction | Fencing | Installation of temporary fencing |

| Construction | Fencing | Removal of temporary fencing |

| Construction | Fencing | Installation of Panel fencing |

| Construction | Fencing | Mix concrete in a wheel barrow |

| Construction | Fencing | Cut fence sheets with electric shears |

| Construction | Fencing | Screw fence sheets to rail using a battery powered drill |

| Construction | Fencing | Install posts |

| Construction | Fencing | Install chainmesh fencing |

| Construction | Fencing | Install star pickets using a hammer and Star Post Dropper |

| Construction | Fencing | Installation of post and rail metal clad fencing |

| Construction | Fencing | Inspection and use of Fastfencer attachment to run out fencing wire/ mesh |

| Construction | Fencing | Cut existing wire ties and unfasten existing fencing wire/mesh from fence posts |

| Construction | Fencing | Drive in fence posts and droppers with a Backhoe & hydraulic vibrating hammer |

| Construction | Fencing | Drive in fence posts and droppers with an Excavator & hydraulic vibrating hammer |

| Construction | Fencing | Clip off wire to the posts using a battery powered clip gun |

| Construction | Joinery | Grinding/ Polishing bench tops with a handheld grinder |

| Construction | Joinery | Installation of new kitchen joinery |

| Construction | Joinery | Install Kick plate |

| Construction | Joinery | Install cupboards |

| Construction | Joinery | Install pre laminated bench top |

| Construction | Joinery | Install wall mounted cupboards to stud wall |

| Construction | Joinery | Cut timber to size using a table saw |

| Construction | Joinery | Adjust hinges to joinery doors |

| Construction | Joinery | Install timber wall linings |

| Construction | Joinery | Install prefabricated steel counter frames |

| Construction | Joinery | Lay Hebel panels into frames and grout into position |

| Construction | Joinery | Install timber wall linings using a battery powered drill |

| Construction | Joinery | Cut wood to size using a table saw |

| Construction | Joinery | Install aluminium skirting |

| Construction | Joinery | Install joinery counters and wall units |

| Construction | Joinery | Position joinery items and level |

| Construction | Joinery | Install Stone Benchtops |